Abstract: Traditional ships use diesel generators to provide power. When the ship docks, in order to save energy and reduce environmental pollution, it should be powered by shore power at the dock. As ships become larger and the power system capacity becomes larger, the requirements for the power supply capacity of dock shore power are also getting higher and higher. Insulation online monitoring provides effective support for the power supply reliability of dock shore power. Online monitoring of the insulation status of the ship's power grid when the ship is berthed can also be achieved by relying on shore power insulation monitoring. Insulation monitoring and fault location can not only avoid some accidents, but also reduce the workload of terminal staff and crew to check whether the distribution network is well insulated.

Keywords: dock shore power; insulation monitoring; fault location; insulation monitoring system.

1. Industry background

The dock shore power system is an important part of building a green and smart port. In the past 20 years, the application and development of shore power at docks in my country has been relatively rapid, and the composition and configuration of shore power systems are relatively flexible. The implementation of relevant national standards and industry standards has laid a good theoretical and practical foundation for the development of dock shore power systems.

As ships become larger and the power system capacity increases, the requirements for the power supply capacity of dock shore power are also getting higher and higher. Insulation online monitoring provides effective support for the power supply reliability of dock shore power. When the ship is berthed, it can monitor the insulation status of the ship power grid. Online monitoring can also be achieved by relying on shore power insulation monitoring. Insulation monitoring and fault location can not only avoid some accidents, but also reduce the workload of terminal staff and crew to check whether the distribution network is well insulated.

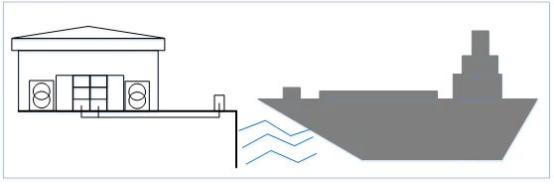

Typical shore power systems are mainly divided into two types: high-voltage shore power systems and low-voltage shore power systems. The voltage and frequency output by commonly used terminal and ship shore power systems around the world are mainly 6kV/50Hz and 400V/50Hz. The power receiving system of low voltage shore power is shown in the figure below.

The substation has two 10kV incoming lines, which are connected to the low-voltage system through a 10/0.4kV transformer. The low-voltage bus outputs multiple feeders, which are connected to multiple shore power boxes. When the ship docks, it connects to the shore power box, stops the diesel generator set, and is powered by low-voltage shore power.

2. System analysis

When the shore power grid is a TN-S system, the hull is not connected to a dedicated grounding wire and the ship's power grid is not connected to the shore power neutral line. When a single-phase grounding fault occurs in a ship's power grid, there is a risk of electric shock if a person stands on the shore and touches the hull. High voltage may appear on the neutral line, and the single-phase grounding current may be large. When the hull is connected to a dedicated grounding wire and the ship's power grid is connected to the shore power neutral line, and a single-phase ground fault occurs in the ship's power grid, the protection device trips, ensuring personal safety, but the continuity of power supply cannot be guaranteed.

When the shore power grid is an IT system and a single-phase ground fault occurs in the ship's power grid, the single-phase to ground short-circuit current depends on the size of the ship's power grid's ground insulation and ground distributed capacitance. The short-circuit current is small, and there is no risk of electric shock when people stand on the shore and touch the hull. Once the ship power grid or another phase of shore power has a short-circuit fault to ground, it will cause a two-phase short circuit, causing the shore power protection device to operate, which may cause harm. Therefore, it is very necessary to conduct insulation monitoring and detect single-phase ground faults in time.

In order to ensure personal safety and avoid fire accidents, the metal hull of the ship should be connected to the grounding device in the shore power device. Shore power should be powered by an ungrounded neutral point system, that is, IT system power supply.

3. Product introduction

Insulation monitoring and fault location products can monitor low-voltage and ungrounded systems in dock shore power systems. This product has rich functions, including insulation resistance monitoring, insulation fault warning, insulation fault alarm, event recording, parameter setting, communication networking, etc. When the system has insulation degradation or grounding fault, it can alarm in time to remind relevant personnel to troubleshoot the fault in time.

Type | Appearance | Instruction |

AIM-T500L insulation monitor |

| AIM-T500L insulation monitor adopts advanced microcontroller technology, has high integration, small size, easy installation, and integrates intelligence, digitization and networking. It has the characteristics of wide measurement range, fast response speed, and large allowable system leakage capacitance. |

ASG200 test signal generator |

| When an insulation fault occurs in the monitored IT system, the ASG200 test signal generator can start in time and generate a test signal. It can cooperate with the insulation fault locator to realize the insulation fault location function and send faulty phase lines. |

AIL200-12 insulation fault locator | | The AIL200-12 insulation fault locator uses a high-precision signal detection circuit and cooperates with the AKH-0.66L series current transformer to detect the signal injected into the system by the ASG200 test signal generator and accurately locate the circuit where the insulation fault is located. A single locator can locate 12 loops. |

AKH-0.66L series current transformer |

| The AKH-0.66L series current transformer is used in conjunction with the AIL200-12 insulation fault locator. The transformation ratio is 1000:1. The current transformer is installed inside the cabinet by directly fixing it with screws. The secondary side is led out through wiring, which is easy to install and use. |

AIM-T500L insulation monitor can monitor the insulation resistance of the IT system to ground in real time and activate a fault warning or alarm function when the resistance exceeds the limit. It has various fault indication methods such as relay alarm output and LED alarm output. It has an event recording function to facilitate operators to view and analyze the fault type and occurrence time, and judge the system operating status. It has a self-test function, which can realize fault self-test of the instrument hardware circuit with one click. It has a disconnection monitoring function and can monitor the PE/KE function grounding wire connection status in real time. It also has one RS485 interface and standard Modbus-RTU protocol.

ASG200 test signal generator can generate a positioning signal and inject it into an ungrounded system to indicate the phase line where the fault is located.

AIL200-12 insulation fault locator can locate and indicate the branch where the fault is located. A single AIL200-12 can locate up to 12 circuits. Each IT system can be connected to up to 90 locators, locating a total of 1080 circuits.

AKH-0.66 L-xx series current transformers are used in conjunction with the AIL200-12 insulation fault locator to achieve fault location. This series has many different specifications. You can choose the appropriate aperture according to the rated current of the loop, and you can choose circular or rectangular transformers. If the site does not have the conditions for power outage construction, you can also choose open-type AKH-0.66 L-xxKN series current transformers.

4. Technical indicators

The technical specifications of AIM-T500L insulation monitor are as follows:

Item | Parameter | |

Accessory power supply | AC 85~265V; DC100~300V; 50/60Hz | |

Power dissipation | < 8W | |

System voltage | AC 0~690V; DC 0~800V; 40~460Hz | |

System application | IT system (online), Other system (offline) | |

Insulation monitoring | Measuring range | 1k~10MΩ |

Alarm range | 10k~10MΩ | |

Resistance accuracy | 1~10k,1k; 10k~10M, ±10% | |

system leakage capacitance | <500μF | |

Response time (Ce=1μF) | <5s | |

Internal parameters | Measuring voltage | <50V |

Measuring current | <270μA | |

Internal DC impedance | ≥180kΩ | |

Relay output | Error, Alarm, Warning | |

SOE | 20 records (fault type, fault value, fault time) | |

Alarm type | LCD, LED indicator | |

Communication | RS485, Modbus-RTU | |

Impulse voltage / Pollution Level | 8kV/Ⅲ | |

EMC/ Radiation | IEC61326-2-4 | |

Environment | Working temperature | -10 ~+65℃ |

Storage temperature | -20~+70℃ | |

Relative humidity | <95%, without condensation | |

Altitude | ≤2500m | |

5. Conclusion

The power supply system of dock shore power has certain particularities and has high requirements on the power grid. When connecting to shore power, on the one hand, a safe and reliable grounding type power grid must be used. On the other hand, the issue of online monitoring of the ship's power grid insulation cannot be ignored. Pay attention to the online monitoring of shore power and ship insulation. The use of insulation monitors provides strong support for the safe and reliable operation of shore power and ships.