Abstract: In the power supply and distribution system of the water treatment industry, load equipment such as aeration fans, lift pumps, and sludge dehydration equipment are involved, which will cause the asynchronous motor to generate more reactive power and a large number of harmonics, thereby reducing the system power factor. At the same time, harmonics also cause great harm to the power distribution system and loads. In this regard, the water treatment industry needs to pay more attention to power quality and use active filtering devices to filter out harmonics, thereby saving energy and reducing consumption.

Keywords: power supply and distribution system in water treatment industry; harmonics; power quality.

1. Main characteristics of power quality in water treatment industry:

1.1 The water treatment industry has developed steadily, and plant construction has steadily increased year by year;

1.2 Loads such as motors and water pumps work for a long time, the power factor is high, and the reactive power compensation is relatively stable;

1.3 The main harmonic source is the frequency converter, and the harmonic content is large, so active filtering equipment needs to be configured for harmonic control.

2. Main equipment in the water treatment industry

The main high-power equipment in sewage treatment plants in the water treatment industry includes aeration fans, lift pumps, sludge dehydration equipment and complete drying equipment, as well as large air-conditioning systems, frequency converters, and ventilation equipment. The frequency conversion mechanisms and control components of these devices are typical nonlinear loads. The generated harmonics flow into the power distribution system and pollute the power grid, which not only has a potential impact on reactive power compensation equipment, but also affects the normal operation of various electrical equipment, reduces system efficiency, and increases power costs.

2.1 Aeration fan

The main function of the sewage treatment aeration fan is to provide oxygen to the pool, and it is mainly used in the grit chamber. The aeration fan is connected to the pipe, and then the pipe is connected to the aeration plate at the bottom of the aeration tank. The aeration fan blows gas into the aeration tank to provide sufficient oxygen for the activities of microorganisms and promote chemical reactions. When the aeration fan is turned on, the power factor is 0.8 and the total harmonic distortion rate is nearly 30%.

2.2 Lift pump

Lift pump is a pump product that integrates pump, motor, casing and control system. The main function is to raise the sewage to a certain height and make it run according to the gravity flow method, which can control the water volume and thereby control the sewage concentration in the reaction tank. The power factor of the lift pump is 0.75, and the harmonic distortion rate is nearly 30% to 40%.

2.3 Sludge dehydration

Dehydration methods mainly include natural drying, mechanical dehydration and granulation. Natural drying method and mechanical dehydration method are suitable for sewage sludge. The granulation method is suitable for coagulation and sedimentation of sludge. Sludge dehydration equipment mainly produces 5th and 7th harmonics. The power factor of sludge dehydration equipment is 0.8, and the harmonic distortion rate is nearly 20%.

2.4 Frequency converter

The main function of the frequency converter is to change the frequency and amplitude of the AC motor's power supply, thereby changing the period of its moving magnetic field to achieve the purpose of smoothly controlling the motor's speed. Using the soft start function of the frequency converter will make the starting current start from zero, and the maximum value will not exceed the rated current, which reduces the impact on the power grid and the requirements for power supply capacity, and prolongs the service life of equipment and valves. Large-capacity inverters need to be used with incoming line reactors, which can effectively prevent disturbance and impact of power components and prevent conflicts with active filters to amplify harmonics. The power factor of the inverter is 0.9, and the total harmonic distortion rate is nearly 30% ~50%.

3. Power quality cases and solutions in water treatment industry

3.1 Accident phenomena

There is a 2000kVA transformer in a sewage treatment plant in Hunan. There are two capacitor compensation cabinets on the low-voltage side of the transformer. The compensation capacity is 1000kVar. The cabinets are equipped with contactor switching, and both are automatically switched. During the debugging and operation of the sewage treatment plant, the operation duty personnel found that a set of capacitors and reactors were burnt in the capacitor compensation cabinet of the low-voltage power distribution room during inspection. Other capacitors and reactors that were not damaged and were put into operation were found through on-site inspection. The temperatures are all between 80 and 100°C, and the noise and temperature of the transformer increase significantly.

3.2 Analysis of causes of damage to capacitor cabinets

1)Quality problems of components such as capacitance and reactance. The inside of the capacitor is filled with poor black glue, which is easy to expand and bulge when overheated; the external material is made of iron casing, which is suitable in coastal cities or places with high salt spray and fog; the reactor is made of aluminum core, and the interface is oxidized and explodes at high temperatures;

2)Fastening issues of electrical connectors during on-site construction and installation. If the interface is loose, the connection point will be locally heated;

3)Parameter matching problem of capacitance and reactance. The series reactance rate does not match. For example, if a capacitor with a reactance rate of 7% for 480V and a reactor with a reactance rate of 14% for 525V are used, the mismatch of capacitance and reactance will lead to resonance;

4)Environmental factors. As the temperature and humidity of the on-site environment change, the capacitive reactance parameters change, leading to the problem of series reactance deviation. Series resonance will occur between capacitors and reactants, causing the current to become larger and causing serious heating;

5)The parallel resonance problem between the capacitor cabinet and the load triggered by the harmonic voltage causes the bus voltage to rise, causing capacitor damage or over-voltage protection or damage to the load equipment.

3.3 Solutions

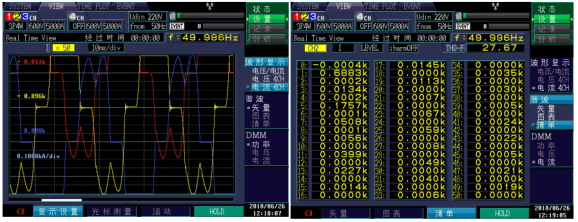

The test point is the main outlet terminal of the transformer. According to the actual measurement results of the power quality of the sewage treatment plant, the total outlet terminal of the transformer contains 5th, 7th, 11th, and 13th harmonics, the total harmonic current reaches 200A, and the harmonic distortion rate reaches 27.6%. After on-site inspection, it was found that the capacitors, reactances and other devices were in good condition and the reactance rates matched. The cause was analyzed to be a fire in the lines and equipment caused by excessive harmonic current. Finally, at the suggestion of our company, a 300A active filter was installed on the outlet side of the transformer. Currently, the on-site harmonic distortion rate is stable below 10%, and the capacitor cabinet operates stably for a long time.

APF active filter adopts DSP+FPGA full digital control method and is connected in parallel in the system to compensate for harmonics and reactive power. It can fully compensate the 2nd to 51st harmonics or compensate specific harmonics. It has complete bridge arm over-current, DC over-voltage protection, and device over-temperature protection functions. It also has the functions of automatic detection operation, measurement monitoring and fixed value setting. It has the functions of intelligent heat dissipation and stepless speed adjustment. It has dynamic expansion function and supports plugging and unplugging for easy replacement.

4. Conclusion

Frequency converters, motors, and water pumps are commonly used in equipment in the water treatment industry, resulting in a rapid increase in the types and quantities of nonlinear equipment loads. Harmonic pollution is becoming increasingly serious, causing great harm to power distribution systems and field equipment. However, the harmonic problem of the power supply and distribution system in the water treatment industry has not received enough attention. Direct and indirect economic losses such as increased power consumption, equipment failure, and shortened service life caused by harmonics are considerable. Active filter devices are of great significance to improving the quality of power supply, improving the safety and economic operation of the power grid, ensuring the performance of equipment and reducing energy consumption.